Rotating Equipment: Types, Functions, and Maintenance

Rotating equipment is essential for productivity and critical processes—from fluid pumping to power generation. Knowing how it works and maintaining it properly reduces downtime, boosts efficiency, and improves safety. This article covers key types, functions, applications, and maintenance tips.

What Is Rotating Equipment?

Rotating equipment refers to machines and mechanical devices that move fluids, gases, or other materials using a rotating element. These tools convert energy from one form to another (usually electrical to mechanical or fluid energy) and include various industrial machinery. Rotating equipment is essential in industries such as:

● Oil and gas

● Power generation

● Chemical processing

● Manufacturing

● Water treatment

● HVAC systems

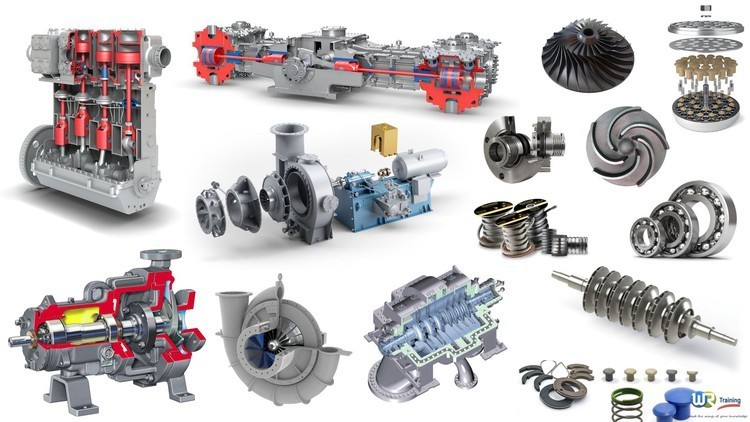

Typical components of rotating equipment include shafts, bearings, seals, impellers, blades, and couplings—all of which are subjected to wear and tear over time due to constant motion.

Common Types of Rotating Equipment

1. Pumps

Pumps move liquids through piping systems, which are essential in water supply, chemical transfer, and refining. Common types include centrifugal pumps, impellers, and positive displacement pumps, which move fixed volumes through discharge.

2. Compressors

Compressors raise gas pressure by reducing volume. Types include centrifugal (for high flow), reciprocating (high pressure), and rotary screw (industrial air systems). They’re crucial in refrigeration, gas processing, and air compression.

3. Turbines

Turbines convert fluid or gas flow into mechanical energy. Common types include steam (power plants), gas (jets, power stations), and hydraulic (hydropower). They’re efficient and vital for energy conversion.

4. Motors and Generators

Electric motors convert electrical energy into motion; generators do the reverse. Together, they power essential industrial operations and backup systems.

5. Fans and Blowers

Fans and blowers move air in HVAC, combustion, and cooling systems. Centrifugal fans push air radially; axial fans move it along the axis. Both are vital for ventilation, temperature control, and air quality.

Functions and Importance of Rotating Equipment

Rotating equipment is essential for energy conversion, fluid transport, airflow control, and system reliability. Its performance directly affects plant efficiency, safety, and operating costs.

However, its use faces several challenges, including vibration, misalignment, bearing failure, seal wear, and thermal expansion—all of which can reduce efficiency and lead to costly downtime. Regular monitoring and proactive maintenance are essential to detect and address these issues early.

Best Practices for Operation and Maintenance

Proper care and handling of rotating equipment can significantly extend its service life and prevent unexpected breakdowns. Here are some best practices:

1. Routine Inspections

Perform regular visual and performance inspections to identify early signs of wear or failure.

2. Predictive Maintenance

Use condition monitoring tools such as vibration analysis, thermography, and oil analysis to predict failures before they happen.

3. Alignment and Balancing

Ensure all rotating components are properly aligned and balanced to reduce stress on parts.

4. Lubrication Management

Maintain proper lubrication schedules and use the right type of lubricant to prevent bearing and seal failures.

5. Operator Training

Equip personnel with the knowledge to operate and monitor equipment correctly. Misuse or neglect can lead to damage.

6. Spare Parts Readiness

Keep critical spare parts in inventory to minimize downtime during repairs.

7. Documentation and Record-Keeping

Track all maintenance activities, inspection results, and equipment performance metrics to guide future decisions.

Keep Your Operations Moving

Rotating equipment is the heartbeat of industrial operations, enabling fluid movement, energy conversion, and environmental control. These machines, from pumps and compressors to turbines and fans, are vital to keeping systems running safely and efficiently.

However, with constant motion comes constant wear. A strong maintenance strategy—backed by skilled operators, regular inspections, and modern monitoring tools—is essential to keeping rotating equipment in peak condition.

Whether you’re managing a power plant, chemical facility, or manufacturing line, understanding your rotating equipment is key to reducing downtime, cutting costs, and maximizing productivity.